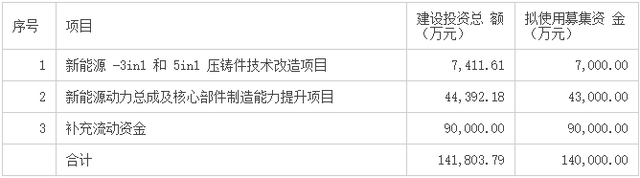

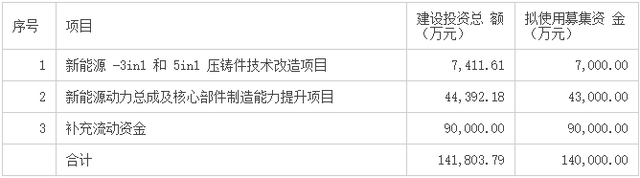

On June 28, Dongfeng Technology announced that it plans to raise 1.4 billion yuan for new energy-3in1 and 5in1 die-casting technological transformation, new energy powertrain and core components manufacturing capacity improvement projects, and supplementary working capital.

my country’s auto parts industry started relatively late, and there is still a certain distance between it and western developed countries in terms of output value structure and key technologies. However, in recent years, my country has made continuous efforts to improve and bridge the gap in related fields, and has achieved outstanding results. From the perspective of the output value ratio of complete vehicles and parts, my country is about 1:1. Although there is a big gap with the 1:1.7 of developed countries in the automobile industry, my country’s back-end maintenance market is gradually improving, and the demand for auto parts will further increase. In addition, the market share of key components such as generators and starters has been occupied by foreign manufacturers for a long time. However, in the context of the continuous improvement of domestic technology levels and the need of major auto manufacturers to save costs, domestic substitution has gradually increased. On the agenda, the demand for domestic auto parts in the vehicle manufacturing industry will increase.

In the field of new energy, the Chinese government’s first support for new energy vehicles has promoted the rapid development and maturity of related technologies, markets, and industrial chains, opening up new markets for auto parts. The integrated electric drive system is an important part of the new energy vehicle, but the manufacturing of the integrated electric drive system in my country started late, and the accumulation of related technologies and talents is still weak, especially the technical level of the driving motor of the core component of the system is lower than that of the international first-class enterprises. larger. High-efficiency, high-adaptability, and lightweight drive motors have high manufacturing barriers. At present, international advanced manufacturers represented by BorgWarner and Bosch have entered the domestic market through joint ventures. The performance advantages of products have caused certain domestic brands. shock. At the same time, some domestic brands with earlier layouts have had a deep accumulation of technology. Under the external environment such as the entry of foreign companies and the decline of subsidies, they have resisted the pressure, strived to improve their own technical level, and promoted the positive development of domestic new energy vehicle manufacturing.

Compared with ferrous metal die castings, non-ferrous metal alloy die castings have higher tensile strength, corrosion resistance, recyclability and lightweight characteristics, and have obvious competitive advantages. With the improvement of die casting equipment and process technology, more and more black Metal castings are replaced by non-ferrous metal die castings such as aluminum alloys and magnesium alloys. In recent years, under the background of low carbon and environmental protection, the state has vigorously supported the development of new energy vehicles. With the launch of the “dual carbon” goal, the penetration rate of new energy vehicles in China’s passenger car market has further increased. As an important strategic direction of energy saving and emission reduction, automobile lightweighting has driven the demand for aluminum and magnesium alloy die-casting products to rise rapidly.

Dongfeng Technology intends to implement this project through its holding subsidiary company, Dongfeng (Shiyan) Nonferrous Casting Co., Ltd. (hereinafter referred to as “Dongfeng Nonferrous”), in order to improve the production and manufacturing capacity of aluminum alloy die castings. The total planned investment of this project is 74.1161 million yuan, and the planned investment of raised funds is 70 million yuan. After the project is completed, Dongfeng Nonferrous Metals will increase the annual production capacity of 905,800 pieces of non-ferrous metal castings.

In the manufacturing of new energy powertrains and core components, the booming environment of the new energy vehicle market has brought new opportunities for related enterprises in my country. Higher requirements require enterprises to improve their research and development capabilities, reduce production costs, improve production efficiency, enhance their ability to meet customer and market demands, improve their own industry competitiveness, and seize market opportunities.

Dongfeng Technology plans to implement this project through its wholly-owned subsidiary Dongfeng Electric Drive System Co., Ltd. (hereinafter referred to as “Dongfeng Electric Drive”), in order to improve the production capacity of independent new energy and powertrain components, improve the level of production technology, enhance The ability to meet customer needs.

The total construction investment of this project is 443,921,800 yuan, of which 430,000,000 yuan is planned to be invested with raised funds. After the project is completed, Dongfeng Electric Drive will form an annual output of 600,806 generators, 867,312 starters, 422,815 drive motors, 153,675 integrated sets Production capacity of electric drive systems.

It is understood that the existing production line of Dongfeng Electric Drive was built earlier, the key process technology level is relatively backward, the automation and intelligence level in the production process is still low, the labor intensity of employees is high, and it is difficult to meet customer needs. In the past customer on-site audit process, the customer frequently gave feedback on the automation and intelligence of the production line, especially put forward higher requirements for the automatic detection capability of some key processes, and put forward higher requirements for the production line with lower automation and intelligence. Process assurance capability is questioned. If Dongfeng Power Drive fails to rectify the audit opinions put forward by customers within a limited time, the customer may reduce the scale of future supply shares, and even affect the customer’s assessment of the ability of Dongfeng Power Drive to undertake new projects, which will affect future business development. Serious impact.

Through the purchase of highly automated and intelligent manufacturing equipment, this project improves automatic detection capabilities, stabilizes product quality, meets customer needs, and reduces labor costs, which is conducive to improving production efficiency, reducing costs, and improving profitability.